Product Description

GPHQ F helical Parallel gearbox motor

GPHQ F helical parallel speed reduction gear box are based on the building block design,so it's convenient for them to fit all types of motors or connect with other power input.The same type of combine can fit motors with different power,so that it's possible for different types of machines to combine or connect.

GPHQ F series speed gear reducer is 1 kind of parallel shaft helical gear reducer , which consist of 2 or 3 stages helical

gears (relate to gear ratio) in the same case . The hard tooth surface gear use the high quality alloy steel ,the

process of carburizing and quenching, grinding 1,Output torque:200-18000(N.m)

1,Rated power:0.12-200(kw)

2,Input speed:≤3000 (rpm)

3,Output speed:≤393(rpm)

4,Transmission ratio:≥3.77

5,Series:2-3

6,Mounting way:M1-M6

GPHQ F helical reducer motor materials :

| housing material: | HT2OO high-strength cast iron for F37,47,57,67,77,87 HT250 High strength cast iron for F97,107,127,157 |

| Gear material: | 20CrMnTi |

| Housing hardness | HBS90-240 |

| Surface hardnesss of gear | HRC58°-62° |

| Gear core hardness | HRC33°-40° |

| Input/Output shaft material | 40Cr |

| Input/Output shaft hardness | HBS241°-286° |

| Shaft at oil seal postion hardness | HRC48 ° -55 ° |

| Machining precision of gears material | Accurate grinding 6-5 grade |

| Efficiency | up to 98% |

| Noise(Max) | 60-68dB |

| Tem.rise: | 40°C |

| Vibration | ≤20um |

| Motor | IP54, F class ,B5 FLANGE |

| color : | blue (if you need big quantity ,we can done as your wanted color ) |

Our reduction geared motor Advantage

1,reasonable price with excellent quality

2,delivery in time

3,safe ,reliable ,economical and durable

4,stable transmission ,quiet operation

5,smooth running and low noise

6,nice appearance ,durable service life

7,high heat-radiating efficiency ,high carrying ability

8,each gearbox must be tested before packing

9.reply in high efficiency during 1 working day

10. professional to produce gearbox and electric motor .

If there is any question, please don't hesitate to contact with me (EVA), U can send us your inquiry. And you will get response in 1 working day.

MOTOR CATALOGUE :

PRODUCING PROCESS:

WORKSHOP EQUIPMENT:

CERTIFICATION :

PACKAGE :

for 1 container, directly loading ,for less, all goods with pallet,

FAQ

1, Q:what's your MOQ for ac gearbox motor ?

A: 1pc is ok for each type electric gear box motor

2, Q: What about your warranty for your induction speed reducer motor ?

A: 1 year ,but except man-made destroyed

3, Q: which payment way you can accept ?

A: TT, western union .

4, Q: how about your payment way ?

A: 100%payment in advanced less $5000 ,30% payment in advanced payment , 70% payment before sending over $5000.

5, Q: how about your packing of speed reduction motor ?

A: plywood case ,if size is small ,we will pack with pallet for less 1 container

6, Q: What information should be given, if I buy electric helical geared motor from you ?

A: rated power, ratio or output speed,type ,voltage , mounting way , quantity , if more is better ,

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Agricultural Machinery |

|---|---|

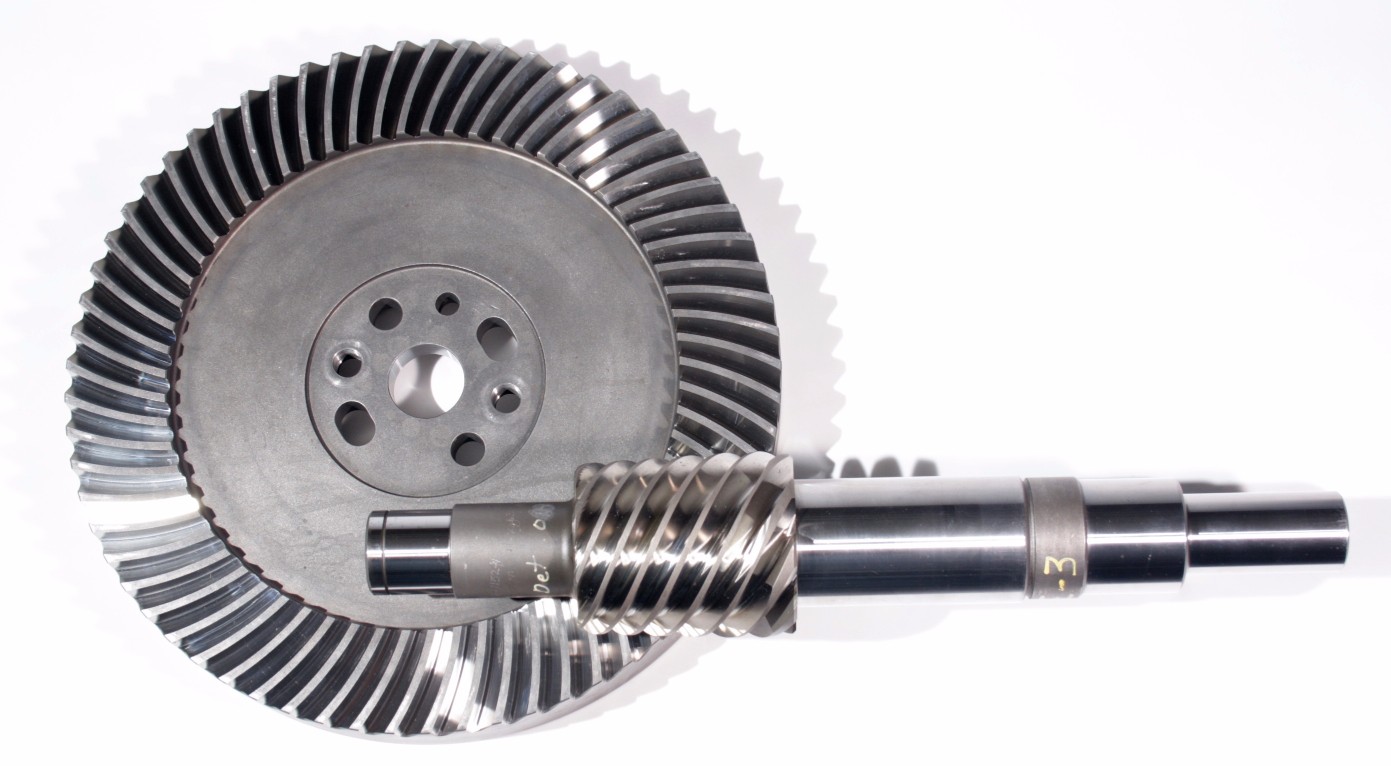

| Layout: | Bevel |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Double-Step |

| Type: | Bevel |

| Customization: |

Available

| Customized Request |

|---|

How do you install a bevel gear system?

Installing a bevel gear system involves several steps to ensure proper alignment, smooth operation, and efficient power transmission. Here's a detailed explanation of how to install a bevel gear system:

- Preparation: Before installing the bevel gear system, gather all the necessary tools and equipment. Ensure that you have the correct bevel gears, shafts, bearings, and any additional components required for your specific application. Familiarize yourself with the system's design, specifications, and installation instructions provided by the gear manufacturer.

- Clean and Inspect: Thoroughly clean all the components of the bevel gear system, including the gears, shafts, and bearings. Inspect them for any signs of damage, wear, or defects. Replace any damaged or worn-out parts to ensure optimal performance and longevity.

- Shaft Alignment: Proper alignment of the shafts is crucial for the bevel gear system's performance. Ensure that the shafts are aligned accurately, both angularly and axially, as specified by the manufacturer. Misalignment can lead to premature wear, increased noise, and reduced efficiency. Use precision measurement tools, such as dial indicators, to achieve the required alignment.

- Bearing Installation: Install the bearings on the shafts according to the manufacturer's instructions. Ensure that the bearings are securely fitted and properly lubricated. Proper bearing installation helps support the shafts, reduces friction, and ensures smooth rotation of the gears.

- Gear Meshing: Carefully position the bevel gears on the shafts, ensuring proper meshing between the teeth. The gear teeth should engage smoothly and evenly without any binding or excessive clearance. Achieving the correct gear meshing is crucial for efficient power transmission and to prevent premature wear or damage to the gears.

- Housing Assembly: Assemble the housing or casing that encloses the bevel gear system. Ensure that all housing components are aligned and securely fastened. Follow the manufacturer's instructions for proper housing assembly, including the use of gaskets or seals to prevent lubricant leakage and contamination.

- Lubrication: Proper lubrication is essential for the smooth operation and longevity of the bevel gear system. Apply the recommended lubricant to the gears, bearings, and other moving parts according to the manufacturer's specifications. Ensure that the lubricant used is compatible with the gear material, operating conditions, and environmental factors.

- Testing and Adjustment: After the installation is complete, perform a thorough system check. Rotate the shafts manually or using a suitable drive mechanism to ensure smooth gear operation, proper alignment, and absence of abnormal noise or vibration. Make any necessary adjustments, such as gear backlash or meshing depth, as per the manufacturer's guidelines and based on the specific application requirements.

It's important to note that the installation process may vary depending on the specific bevel gear system and application. Always refer to the manufacturer's instructions and guidelines for the particular gear system you are working with to ensure proper installation and optimal performance.

In summary, installing a bevel gear system involves preparation, cleaning and inspection, shaft alignment, bearing installation, gear meshing, housing assembly, lubrication, and thorough testing and adjustment. Following proper installation procedures and adhering to manufacturer guidelines are essential to achieve efficient power transmission, smooth operation, and the desired performance from the bevel gear system.

How do you retrofit an existing mechanical system with a bevel gear?

Retrofitting an existing mechanical system with a bevel gear involves modifying the system to incorporate the bevel gear for improved functionality or performance. Here's a detailed explanation of the retrofitting process:

- Evaluate the Existing System: Begin by thoroughly evaluating the existing mechanical system. Understand its design, components, and operational requirements. Identify the specific areas where the introduction of a bevel gear can enhance the system's performance, efficiency, or functionality.

- Analyze Compatibility: Assess the compatibility of the existing system with the integration of a bevel gear. Consider factors such as available space, load requirements, torque transmission, and alignment feasibility. Determine if any modifications or adaptations are necessary to accommodate the bevel gear.

- Design Considerations: Based on the system evaluation and compatibility analysis, develop a design plan for incorporating the bevel gear. Determine the appropriate gear type, size, and configuration that best suits the retrofitting requirements. Consider factors such as gear ratio, torque capacity, tooth profile, and mounting options.

- Modify Components: Identify the components that need modification or replacement to integrate the bevel gear. This may involve machining new shafts or shaft extensions, modifying housing or mounting brackets, or adapting existing components to ensure proper alignment and engagement with the bevel gear.

- Ensure Proper Alignment: Proper alignment is crucial for the successful integration of the bevel gear. Ensure that the existing system components and the bevel gear are aligned accurately to maintain smooth and efficient power transmission. This may involve adjusting shaft positions, aligning bearing supports, or employing alignment fixtures during the retrofitting process.

- Lubrication and Sealing: Consider the lubrication requirements of the bevel gear system. Ensure that appropriate lubricants are selected and provisions for lubrication are incorporated into the retrofit design. Additionally, pay attention to sealing arrangements to prevent lubricant leakage or ingress of contaminants into the gear system.

- Testing and Validation: After the retrofitting process is complete, conduct thorough testing and validation of the modified mechanical system. Ensure that the bevel gear functions as intended and meets the desired performance requirements. Perform functional tests, load tests, and monitor the system for any abnormalities or issues.

- Maintenance and Documentation: Develop a maintenance plan for the retrofitted system, including periodic inspection, lubrication, and any specific maintenance tasks related to the bevel gear. Document the retrofitting process, including design modifications, component specifications, alignment procedures, and any other relevant information. This documentation will be valuable for future reference, troubleshooting, or potential further modifications.

Retrofitting an existing mechanical system with a bevel gear requires careful planning, engineering expertise, and attention to detail. It is recommended to involve experienced gear engineers or professionals with expertise in retrofitting processes to ensure a successful integration and optimal performance of the bevel gear within the system.

By retrofitting an existing mechanical system with a bevel gear, it is possible to enhance its capabilities, improve efficiency, enable new functionalities, or address specific performance issues. Proper analysis, design, and implementation are essential to achieve a successful retrofit and realize the desired benefits of incorporating a bevel gear into the system.

Can you explain the concept of straight and spiral bevel gears?

Straight and spiral bevel gears are two common types of bevel gears that have different tooth geometries and characteristics. Here's a detailed explanation of the concept of straight and spiral bevel gears:

Straight Bevel Gears:

Straight bevel gears are a type of bevel gears with straight-cut teeth that are machined on the cone-shaped surface of the gears. The teeth of straight bevel gears are parallel to the gear axis and intersect at a 90-degree angle. These gears are often used when the intersecting shafts need to transmit rotational motion at a right angle.

Straight bevel gears have the following characteristics:

- Tooth Engagement: In straight bevel gears, the tooth engagement occurs gradually as the gears rotate. This results in a relatively smooth and continuous transfer of power between the gears.

- Noise and Vibration: Straight bevel gears can produce more noise and vibration compared to other types of bevel gears, particularly at higher speeds. The straight-cut teeth create impact and noise during the engagement process.

- Efficiency: Straight bevel gears have relatively high efficiency due to their simple tooth geometry and direct engagement.

- Applications: Straight bevel gears are commonly used in applications such as automotive differentials, hand drills, and other mechanical power transmission systems where a 90-degree change in direction is required.

Spiral Bevel Gears:

Spiral bevel gears are another type of bevel gears with curved teeth that are machined on the cone-shaped surface of the gears. The teeth of spiral bevel gears are cut in a spiral pattern, gradually curving along the gear surface. This spiral tooth geometry provides several advantages over straight bevel gears.

Spiral bevel gears have the following characteristics:

- Tooth Engagement: Spiral bevel gears have a more gradual and smoother tooth engagement compared to straight bevel gears. The spiral-shaped teeth allow for progressive contact between the gears, resulting in reduced impact, noise, and vibration.

- Noise and Vibration: Spiral bevel gears produce less noise and vibration compared to straight bevel gears due to their improved tooth engagement characteristics.

- Load Capacity: Spiral bevel gears have higher load-carrying capacity compared to straight bevel gears due to the increased contact area between the gear teeth. This makes them suitable for applications that require higher torque transmission.

- Efficiency: Spiral bevel gears have slightly lower efficiency compared to straight bevel gears due to the sliding action between the teeth during engagement. However, advancements in gear design and manufacturing techniques have improved their efficiency.

- Applications: Spiral bevel gears are commonly used in applications where smooth and quiet operation is required, such as automotive rear axle drives, machine tools, and industrial machinery.

In summary, straight bevel gears have straight-cut teeth that intersect at a 90-degree angle, while spiral bevel gears have curved teeth that engage in a spiral pattern. Straight bevel gears are suitable for applications that require a right angle change in direction, while spiral bevel gears provide smoother engagement, reduced noise, and higher load-carrying capacity. The selection between straight and spiral bevel gears depends on the specific requirements of the application, including the desired level of noise, vibration, efficiency, and torque transmission.

editor by Dream 2024-05-09